No products in the cart.

Combination Alarm SERIE 2

*To a quote contact our technical and sales advisors. Your information must be valid and true (name, full address, email, phone number, country, postal code, I.D. tax status).

*We always require clear specifications in order to make a formal quote.

- Description

- Alarm Specifications

- Valve Box Specification

- Brochure

- Internet Connect

- Gauges Warning

- Legal Notice

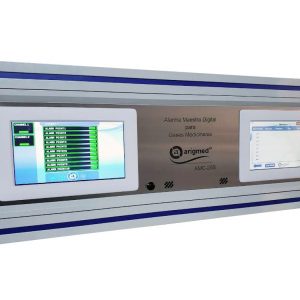

Description

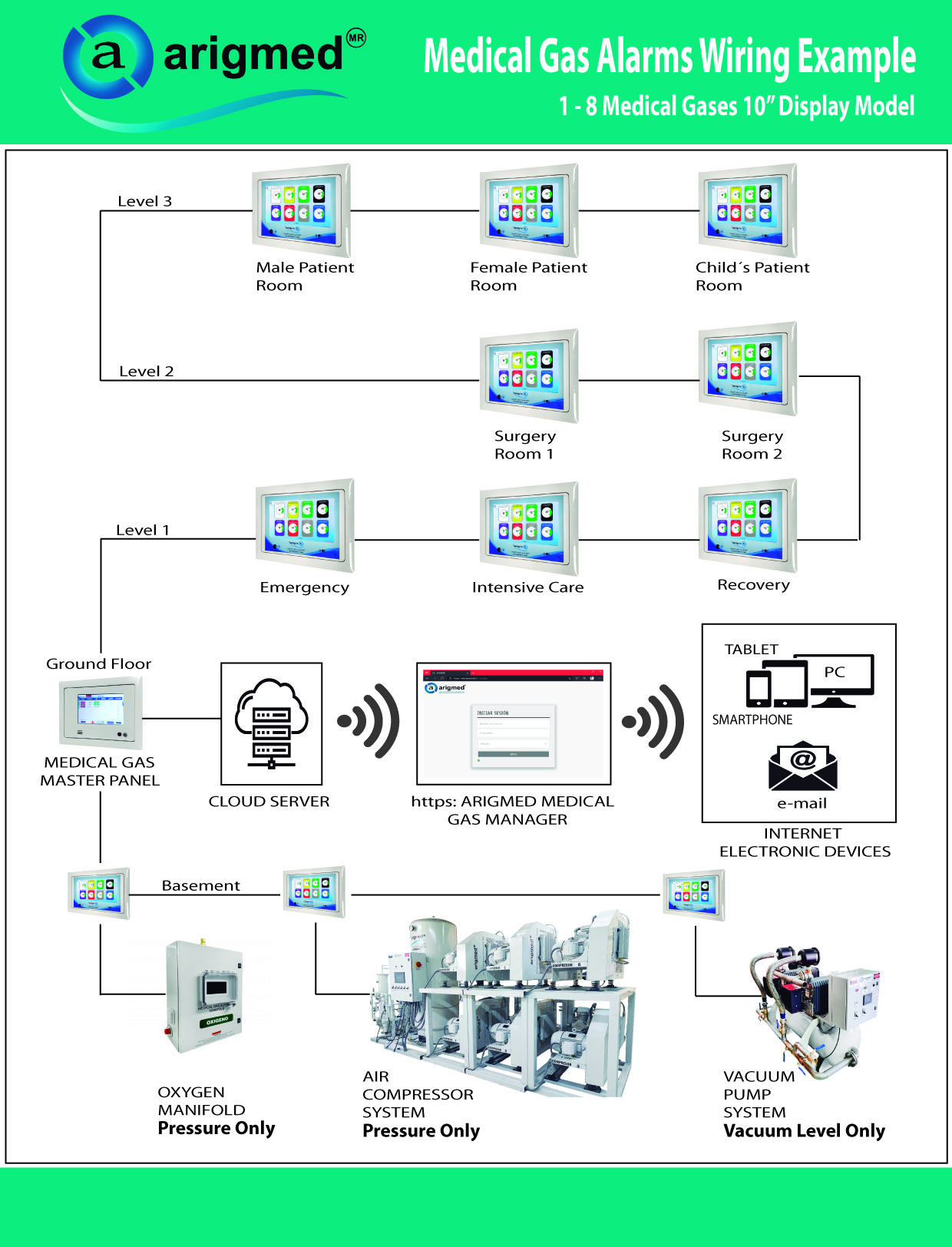

Combinated alarm panel (10" display zone or area alarm + shut-off valve box for medical gases and vacuum), includes:

- One 10" configurable display zone or area alarm, supporting 1 to 8 medical gases and vacuum modules

- One shut-off valve box for medical gases and vacuum, with 1 to 8 valves, excluding diameters of 51 mm or 2” and above

- Complies with NFPA 99 standard

Alarm Specifications

⚙️ Technical Specifications

🔧 Cabinet

- Manufactured from high-resistance ABS thermoplastic injection

- Complies with NFPA 286

- White finish

- Installation available for flush-mount or surface-mounted on wall (must be specified to the factory)

🔢 Alarm Capacity (Number of Gases)

- Configurable display supporting 1 to 8 modules for medical gases and vacuum per alarm

- Maximum network capacity: 127 gas or surgical vacuum sensors for connection to the master panel

💡 Graphics and Visual Indicators

- Real-time pressure and vacuum reading via 10″ full-color LCD display

- Option for NFPA99 color coding and medical gas nomenclature

- Option for ISO color coding and medical gas nomenclature

- Alarm flashing per gas module on display

- Display of medical gas sensor disconnections and cross-connections

- Display of the name of the area where the zone alarm is located

- Possibility to duplicate any gas and/or vacuum module, without exceeding the maximum of 8 modules

🚨 Alarm Events

- Detection of real-time high/low pressure and low vacuum levels

- Detection of medical gas and vacuum sensor signal interruption (disconnection)

- Detection of medical gas and vacuum sensor swap or cross-connection

- On-screen warning if alarm activation parameters deviate from NFPA99 standards

🔌 Communications

- RJ45 female ports for data input and output

- One dry-contact relay output port

- Communication protocol: RS485 serial connection for integration with zone alarm groups and Series 2 master panel (Arigmed source equipment)

- Connection to INTRANET and EXTRANET (INTERNET) via Arigmed ETHERNET INTERFACE with HTML for remote system visualization on PC, tablet, or smartphone through website

🏭 User Functions and Adjustments

- User-modifiable parameters for unit conversion (psi or bar), cut-off levels, and hysteresis

- Editable name of the area where the zone alarm is installed

🎛️ Controls

- On-screen button to mute alarm sound (automatic reset after 1 hour if pressure is not normalized)

- On-screen system test button

📘 Installation, Operation and Maintenance Manual

- Protected document, exclusive to brand equipment

- Request via email and form found in the Manuals and After-Sales Service section

🔗 Required Complementary Equipment

- Remote digital pressure/vacuum sensor connected to the medical gas network

- DISS DEMAND CGA V-5 check valve installed on supply line

- Flush-mount box for electrical, data, and gas/vacuum connections

- Belden STP cable #8461ZH or #8208 for additional relay port (point-to-point connection, no splices for relay system)

- Minimum UTP CAT 6 data cable for serial segment alarm connection (point-to-point, no splices)

- Power supply: 110–220 V, 50–60 Hz

- Arigmed Ethernet Interface for HTML access; remote pressure monitoring via Arigmed website (hosting on Arigmed site may incur additional charges)

- Users can receive real-time email notifications of medical gas alarm events

- Requires stable, high-quality fixed internet access

⚠️ Conditions to Avoid

- Voltage fluctuations in the electrical supply

- Use of emergency power generators as the primary source

- Intermittent or unstable electrical supply

- Frequent power loss with repeated emergency generator activation

🛠️ Installation Recommendations

- Verify physical grounding connection

- Install No-Break electrical backup system

- Install surge protector for protection against electrical discharges

Valve Box Specification

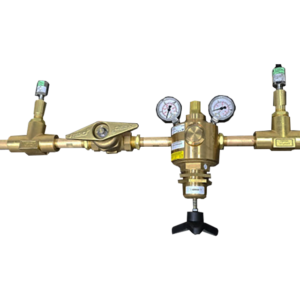

🧰 Shut-Off Valve Box for Medical Gas Control

Complies with NFPA 99 standard🔧 Valves

- Made from three-piece brass with solderable ports

- Stainless steel ball-type shut-off, with PTFE seals

- Rated for 600 W.O.G. (Water, Oil, Gas)

- Extensions in Type “L” or “K” copper tubing

- ¼-turn operation, controlled by lever or handle

🔌 Ports for Pressure/Vacuum Gauges and DISS DEMAND Valves for Digital Alarm Sensors

- Manufactured from brass

- ¼” straight female thread on both ends of the valve

📈 Pressure and Vacuum Gauges

- 1½” dial, back connection

- Glass viewing window, carbon steel housing with black electrostatic finish

- Optional stainless steel housing (upon specification)

| Measurement Type | Range | Application |

|---|---|---|

| Positive | 0–11 kg/cm² (0–160 PSI) | General use |

| Positive | 0–21 kg/cm² (0–180 PSI) | Nitrogen and Instrument Air |

| Negative | 0–76 cmHg (0–30″ Hg) | Vacuum |

🛡️ Gauge Protection

- Made from injected PVC, color-coded to correspond with medical gas type

🏷️ Signage

- Identification sign in stainless steel with label indicating:

- Type of gas or vacuum (medical or anesthetic gas scavenging)

- Nomenclature and color coding per NFPA 99-2015

- Graphic indicator showing flow direction

📦 Enclosure

- Made from galvanized steel sheet, finished in white powder-coated electrostatic paint

- Reinforced high-resistance ABS plugs to insulate copper tubing from galvanized steel

- Standardized dimensions according to the number of valves installed

🪟 Access Window

- Hinged: aluminum sheet with white electrostatic paint

- 3 mm transparent acrylic window, pivot hinges and magnetic latch

⚙️ Optional Features

- Specific gas DISS DEMAND connection at the “emergency port” (upon factory request)

📘 Installation, Operation and Maintenance Manual

- Protected document, available exclusively for equipment of our brand

- To request, the user must send an email with the required information using the form in the Manuals and After-Sales Service section

Brochure

Download:No Available

Internet Connect

🔔 Enhanced Version

Our alarm system allows real-time monitoring over the internet. From the pressure recorded in each connected gas module to the statistical history of alarm events over defined periods, all information is instantly available. Additionally, the system can send email alerts and notifications, and is accessible from any internet-connected device — whether a smartphone, tablet, or computer — through our website.Gauges Warning

⚠️ Considerations Regarding Analog Pressure and Vacuum Gauges

Analog devices for positive and negative readings (pressure and vacuum gauges) are not eligible for exchange and are not covered by warranty, due to the fragile nature of their mechanism, which is prone to damage from mishandling or abuse.🚫 Recommendations to Prevent Damage

- Do not use these devices for pressure testing. They are designed exclusively to operate within normal working pressure ranges

- Avoid water hammer during gas pressurization when the devices are mounted in assemblies

- Respect the pressure and vacuum ranges indicated on the gauge dials

- Do not expose the devices to extreme environments such as hot, humid, or tropical climates, nor to corrosive or non-corrosive liquids. In case of corrosion, replacement will be necessary

- Protect the devices from drops, impacts, or physical abuse. These may cause misalignment of the indicator or pointer, as well as damage from overpressure or water hammer beyond the design range

Legal Notice

Intellectual and industrial property: All rights reserved.- All access to this website is subject to the following conditions: The reproduction, permanent storage and dissemination of the contents or any other use that has a public or commercial purpose is forbidden without prior written notice and approval of Grupo Arigmed S. de R.L. de C.V.

- All documents, images and contents, on this website are from the Intellectual property of Grupo Arigmed S. de R.L. de C.V., any type of copy, plagiarism or similarity in those (documents, images and contents), will be object of legal actions to avoid its use by unauthorized persons, organizations or companies, as well to compensate author´s damage caused.