No products in the cart.

Deward type Automatic Medical Gas Manifold

*To a quote contact our technical and sales advisors. Your information must be valid and true (name, full address, email, phone number, country, postal code, I.D. tax status).

*We always require clear specifications in order to make a formal quote.

Description

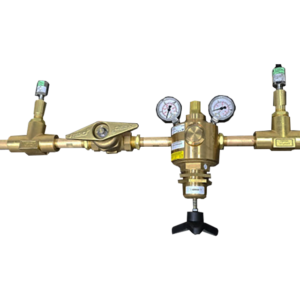

Deward-Type Cylinder Manifold for Automatic Bank Switchover (Medical Type), for indoor use only.

- Complies with NFPA99 standard.

- Complies with ASTM B819 code (clean for oxygen use).

- Deward cylinder evaporators must operate correctly under high oxygen demand to prevent manifold freezing caused by inefficient liquid evaporation.

- An external vaporizer with sufficient capacity for system consumption must be implemented if Deward cylinder evaporators are insufficient.

- Operation and maintenance personnel must be certified for safe equipment operation.

- Gas purity and container integrity are always the supplier’s responsibility.

- Do not use oil or derivatives.

Specifications

🧱 Cabinet

- Indoor use, NEMA 12 rating, IP56 protection level

- Manufactured by Rittal, with baked electrostatic powder coating

- CE certified

⚙️ Control System

- Electronic control via high-speed PCB

- 10” color LCD touchscreen

- Electric valve 110–220 VAC, normally open

- Check valves

- 4–20 mA pressure transducers for high and low pressure

📊 Graphical Display

- Real-time high/low pressure readings for primary and secondary banks

- Real-time high/low pressure readings on supply line

- Pressure unit display

- Status indicators and alarm signals

🚨 Alarm Signals

- Low delivery line pressure

- Active bank empty

- Backup bank activation

- High pressure (above 20% nominal)

- Leak (≥25% pressure drop in backup bank)

🔁 Bypass System

- Two final line regulators for low pressure

- Manual isolation via stainless steel ball valves

- Configuration: one active, one in reserve

🔒 Overpressure and Venting System

- Interconnected relief valve circuit

- Venting directed outside cabinet

🆘 Emergency Inlets

- DISS CGA V-5 fitting, matched to the system’s medical gas

- Located upstream of final regulators, limited to 50–55 PSI low pressure

📈 Pressure Gauges

- Analog type, for high and low pressure stages

🔗 Communication Systems

- Dry contact relay outputs for remote alarm monitoring

- BMS integration via relays

- Modbus RTU RS485 slave mode for PSI pressure and alarm monitoring from BMS, SCADA or master systems

- Main bank selector button

🌬️ Flow Delivery

- Standard flow rate: 65 SCF/min

- For higher requirements, consult the factory

🧱 Cylinder Headers: Minimum Cylinder Pressure and Operating Pressure

- Modular assembly design

- Made of special extruded red brass tube, SPS alloy 23000, H58 Drawn temper

- Complies with ASTM B-43-98 and ASTM B-819 (oxygen-clean)

- Operating pressure: 3,000 PSI

- Minimum Deward cylinder pressure: 230 PSI

- Brass CGA check valves for automatic shutoff

- Manual master valve for open/close control on primary and secondary banks

- Delivered in natural brass finish (installer may coat or paint as preferred)

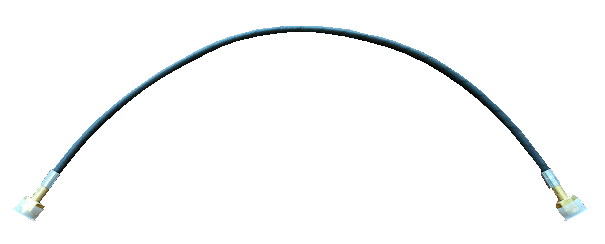

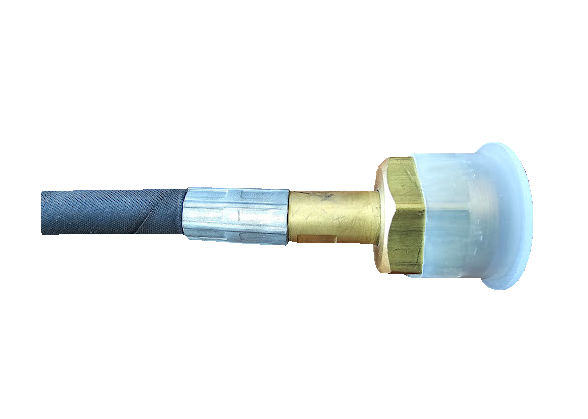

🔗 Cylinder Pigtails

- Oxygen: Flexible copper tube, CGA 540 connection

- Other non-corrosive gases: Flexible PTFE hose with stainless steel mesh cover and safety line, CGA connection specific to each gas

🧪 Gas Compatibility

System available exclusively for high-pressure gaseous cylinders, compatible with:| Medical Gas | State | CGA Connection |

|---|---|---|

| Medical Oxygen | Gaseous, with Deward cylinder evaporator | CGA 540 |

| Nitrogen | Gaseous, with Deward cylinder evaporator | CGA 580 |

⚡ Electrical Requirements

- Power: 100–220 V, 50–60 Hz

🔌 Network Wire Type

- Recommended wire: Belden STP (shielded twisted pair)

- Models: #8461ZH or #8208

⚠️ Conditions Affecting Operation

Avoid the following to ensure proper equipment function:- Voltage fluctuations in power supply

- Emergency power plants used as primary source

- Intermittent or unstable electrical supply

- Frequent outages with repeated emergency generator activation

🛠️ Installation Recommendations

- Verify proper physical grounding of equipment

- Install electrical backup system (No-Break) to prevent interruption

- Add surge suppressors to protect against power spikes or voltage fluctuations

📘 Installation, Operation and Maintenance Manual

This manual is protected and available exclusively for equipment from our brand. To request it, the user must send an email with the required data using the form provided in the manuals and after-sales service section.Brochure

Download:No Available.

Legal Notice

Intellectual and industrial property: All rights reserved.- All access to this website is subject to the following conditions: The reproduction, permanent storage and dissemination of the contents or any other use that has a public or commercial purpose is forbidden without prior written notice and approval of Grupo Arigmed S. de R.L. de C.V.

- All documents, images and contents, on this website are from the Intellectual property of Grupo Arigmed S. de R.L. de C.V., any type of copy, plagiarism or similarity in those (documents, images and contents), will be object of legal actions to avoid its use by unauthorized persons, organizations or companies, as well to compensate author´s damage caused.