Quick Connect Medical Gas Outlet Puritan Bennet type

To quote the equipment, you must specify the following:

To quote the equipment, you must specify the following:

* Specify gas type.

* Installation version (wall, architectural or ambulance).

*For a formal quote, download the equipment configuration sheet, click here and fill in the form, add it to your information providing valid data (name, full address, email, telephone, country, postal code).

Hi, I have a doubt about quick connect Medical Gas Outlet Puritan Bennet type

Description

Medical Gas Outlet quick connect Puritan Bennet type geometric inlet connection for each specific gas. Manufactured with NFPA99 and ASTM B819 compliance codes (Clean for oxygen use).

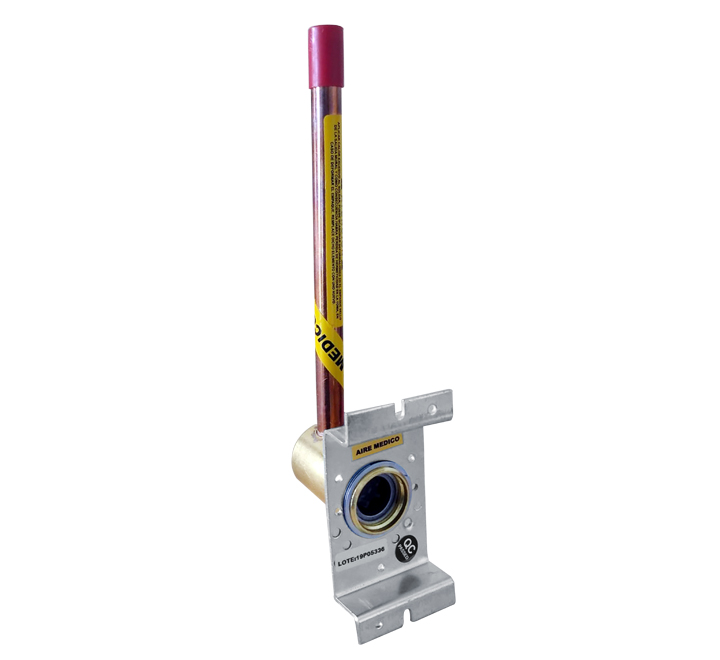

Primary Valve (Back Assembly):

- Brass made Primary valve 360°rotation, copper piping extention “K" type 10mm (internal diameter).

- Polypropylene injection ckeck valve.

- Thermoplastic injection TPVs FDA grade seals.

- Wall and Architectural (Patient Bedhead Units) Hardware Mounting Modular assembly, carbon steel sheet 18 gauge nickel finish made.

- Ceiling Hardware Mounting Modular assembly available, upon request.

- Stainless steel spiral locks.

- “Pin-Guide" No cross connection safety system die-cut corresponding to a specific medical gas type to Rough-in assembly insertion.

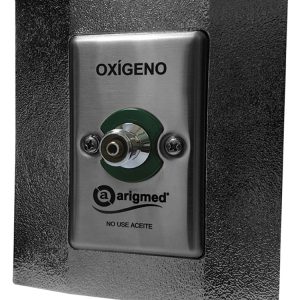

Secondary Valve (Rough-in Assembly):

- Stainless steel front plate made with brass feeding valve, it includes a plunger for connection and disconnection of secondary equipment, fastening to the primary valve is by millimeter screws.

- Geometric inlet connection for each specific gas correspond to Puritan Bennet technology.

- Brass made check valve.

- Thermoplastic injection TPVs FDA grade seals.

- Stainless steel spiral locks.

- ABS plastic injection trim wall plate chrome finish, same material to architectural equipments trim plate, chrome finish.

- “Pin-Guide" No cross connection safety system corresponding to a specific medical gas type to Back-assembly reception.

- zamak chrome finish trim wall plate option (upon request).

Medical Gas Outlet Flow:

- 240 L.P.M. gas flow (if diameters of the main medical gas piping allow it).

- 90 L.P.M. to medical vacuum extraction (if diameters of the main medical vacuum piping allow it).

Load Capacity:

- 450g Maximum load capacity.

Attention

- It should not be cleaned with “CHLORINE" or its derivatives, it could cause corrosion in stainless steel.

Specifications

Legal Notice

Intellectual and industrial property: All rights reserved.- All access to this website is subject to the following conditions: The reproduction, permanent storage and dissemination of the contents or any other use that has a public or commercial purpose is forbidden without prior written notice and approval of Grupo Arigmed S. de R.L. de C.V.

- All documents, images and contents, on this website are from the Intellectual property of Grupo Arigmed S. de R.L. de C.V., any type of copy, plagiarism or similarity in those (documents, images and contents), will be object of legal actions to avoid its use by unauthorized persons, organizations or companies, as well to compensate author´s damage caused.