No products in the cart.

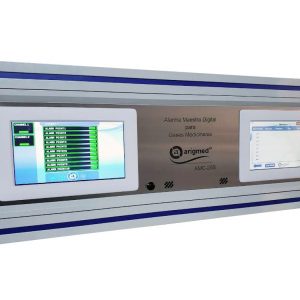

Combination Alarm

*To a quote contact our technical and sales advisors. Your information must be valid and true (name, full address, email, phone number, country, postal code, I.D. tax status).

*We always require clear specifications in order to make a formal quote.

Description

Combination alarm includes a high and low pressure detection alarm with a green numerical segment display and an electromechanical master panel alarm relay type. Available only in a wall-mounted enclosure, meeting NFPA 99.

Cabinet:

- Cabinet manufactured from special extruded aluminum profiles, 6063 temper 5 alloy, powder coating finish.

- Wall-mounted only.

Gases numeber for numerical segment alarm:

- 1 to 6 medical gases modules contained in alarm enclosure.

Graphics and Visual:

- Real-time display of readings on the numerical segment display in green for pressure and vacuum.

- High-visibility green LEDs for normal status.

- High-visibility red LEDs with intermittent flashing for high and low pressure alarm events.

- Numerical display with “ERROR" code for disconnections and cross-connections of medical gas sensors.

- High-visibility green LED to indicate that the alarm is energized.

Alarm Events:

- Alarm for the detection of high and low pressure events in real time.

- Alarm for the detection of signal interruption in the sensors (disconnection).

- Alarm for the detection of medical gas sensor swapping or cross-connection.

Communications:

- 1 Relay port (dry contacts) per alarm cabinet.}

- RS485 communication protocol via serial connection for linking with zone alarm groups and with the Arigmed SERIES 2 Relay master alarm panel (source equipment).

Factory adjusts:

- PSI standard units; to BAR, must be requested to the factory in advance.

Controls:

- A push-button audible alarm cancellation, with a reset after 1 hour if the pressure or vacuum has not returned to normal.

- A push-button alarm system test.

Master Panel Relay type Alarm:

Number of Signals:

- In multiples of 10-signal modules and up to 60 signals contained in a single master relay alarm panel cabinet (minimum 10 signals and maximum 60 signals for a single cabinet).

Visual and Audio Signals:

- High-visibility green LEDs for normal status on each signal module.

- High-visibility red LEDs for alarm events on each signal module.

- High-visibility green LED to indicate that the alarm is energized.

- An audible buzzer for alarm events can only be canceled on-site.

Alarm Events:

- Alarm for real-time detection of “abnormal" events.

Communications:

- Relay ports to receive the signal from each relay zone alarm.

Controls:

- One button to cancel the audible alarm, with a reset after 1 hour if the alarm status has not been normalized.

- One button to test the alarm system.

Installation, Operation and Maintenance Equipment Manuals:

- Manuals are protected and is only for arigmed´s equipments. User must send an email with the information requested in the form in the manuals and after-sales service section in this web site click here ,and then complete the requested form.

Specifications

Following additional equipment is required for operation:- Remote digital pressure/vacuum sensor, connected to the medical gas network.

- Diss Demand CGA V-5 check valve installed in the pipeline for connection to the Arigmed digital sensor.

- Wall-mounted box to house power and data cable connections.

- When the additional Relay Port is used, Belden STP (Shield Twisted Pair) #8461ZH or #8208 network cable is required for point-to-point connections (splices are not permitted). The wire gauge may vary depending on the connection distance from the master relay panel.

- Network cable: UTP (Unshielded Twisted Pair) CAT 6 minimum for SERIAL point-to-point connections (splices are not permitted).

- Power supply: 110-220V 50-60Hz.

- Both data transmissions cannot be used simultaneously.

- Voltage variations in the electrical supply.

- Emergency power supplies.

- Variable or Intermittent Power Supply (power is lost and recovered frequently in a short period of time).

- Continuous and Intermittent Power Supply (when power is lost and emergency power is repeatedly activated).

- Check the equipment’s physical ground connection (to protect against unwanted surges).

- Install a voltage variation and power backup system (No-Break).

- Install a surge suppressor system (to protect the equipment against power variations and surges).

Brochure

Download:

No available.

Legal Notice

Intellectual and industrial property: All rights reserved.- All access to this website is subject to the following conditions: The reproduction, permanent storage and dissemination of the contents or any other use that has a public or commercial purpose is forbidden without prior written notice and approval of Grupo Arigmed S. de R.L. de C.V.

- All documents, images and contents, on this website are from the Intellectual property of Grupo Arigmed S. de R.L. de C.V., any type of copy, plagiarism or similarity in those (documents, images and contents), will be object of legal actions to avoid its use by unauthorized persons, organizations or companies, as well to compensate author´s damage caused.