No products in the cart.

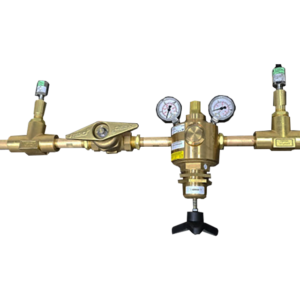

Deward type Automatic Medical Gas Manifold

*To a quote contact our technical and sales advisors. Your information must be valid and true (name, full address, email, phone number, country, postal code, I.D. tax status).

*We always require clear specifications in order to make a formal quote.

Hi, I have a doubt about Deward Type Automatic Medical Gas Manifold

Description

Medical Gas Automatic Manifold for Deward type cylinder headers, meeting NFPA99 and ASTM B819 (clean for oxygen use). The parts that make up the construction of our cylinder manifolds are specifically or custom-made, we do not use commercial parts and connectors.

Cabinet:

- Indoor use, NEMA class 12 IP56 protection level cabinet, in Rittal brand powder coating finish with CE certificate.

- Indoor-Outdoor use, NEMA class 3 IP56 protection level cabinet, in Rittal brand powder coating finish with CE certificate.

- Weatherproof-Outdoor, NEMA Class 4X IP56 rated enclosure, in polished stainless steel finish 3.

Control System:

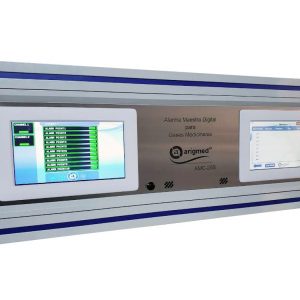

- High speed electronic PCB with 7 " full color LCD display, touch screen control.

- 110-220 vac normally open electric valve.

- Non-return valves

- 4-20Map high and low pressure transducers

Graphics:

- High and Low pressure Display readings for primary and secondary deward cylinder headers in real time.

- High and Low pressure Display readings for manifold final pressure delivery in real time.

- Pressure units.

- Alarm signals.

Signals (Alarms):

- Low delivery pressure alarm.

- Main cylinder header empty alarm.

- Backup cylinder header in use alarm.

- High pressure alarm (above of 20% of nominal pressure).

- Leak alarm (25% pressure drop detected in the reserve or stand by cylinder header).

Minimum Pressure of Deward Cylinders:

- 230 PSI

By-pass System:

- 2 low pressure final line regulators with manual isolation stainless steel ball valves (one regulator in use and the other in reserve).

Over-pressure and vent valve system:

- Interconnected circuit protection system of relief valves, over-pressure guided to the exterior of cabinet manifold.

Comunication System:

- 5 alarms Relay type (Dry Contact) connections to a remote master panel alarm connection, as well an integration of a remote monitoring and administration system BMS (Building Management System) common language based on relay switching.

- Two-wire Modbus RTU RS485 communication in slave mode for monitoring pressures in PSI units and alarm conditions from a BMS (Building Management System), SCADA (Supervisory Control and Data Acquisition) system or any equipment configured as master panel.

- Main Cilynder Header use choosing button.

Emergency Ports:

- Located Before end-line regulators and only for low pressure 50-55 PSI.

- Coupling with CGA inlet according to the medical gas of the Manifold.

Pressure Gauges:

- To high and low pressure analog type.

Installation, Operation and Maintenance Equipment Manuals:

- Manuals are protected and is only for arigmed´s equipments. User must send an email with the information requested in the form in the manuals and after-sales service section in this web site click here ,and then complete the requested form.

- Do not use Oil and its Derivatives.

- Operation and maintenance personnel must be certified for the manifold safe operation. Quality and Medical Gases Purity Degree, as well condition of containers, cylinders and their connections will be always responsibility of the medical gases supplier. Deward cylinder evaporators must work properly in the event of an oxygen over demand to avoid freezing of the manifold due to inefficient liquid evaporation. An external vaporizer with sufficient capacity for consumer demand should be used in case that Deward cylinder evaporators will be insufficient.

Specifications

Flow Delivery:- Standard Flow Delivery of 65 Scf/min.

- For larger deliveries, consult the factory in advance.

- Modular Assembly.

- Red brass tube special extrusion SPS alloy 23000, H58 Drawn temper made, complies with ASTM B-43-98, ASTM B-819 (Clean for oxygen use) 3,000 PSI working pressure.

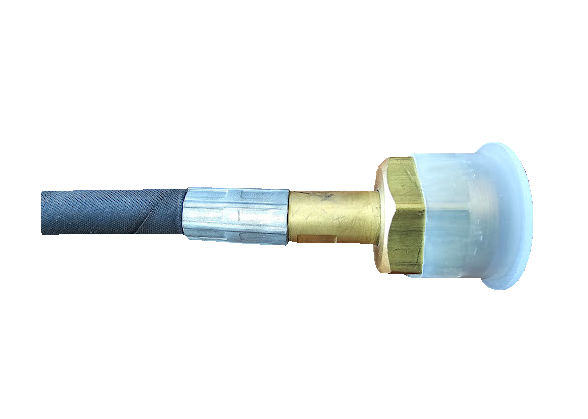

- CGA connection points for each cylinder with self-closing non-return valves (check) brass made.

- Manual master valve to opening and closing control of the primary and secondary cylinder headers.

- Relief valve to each cylinder headers.

- It is delivered in a natural brass finish (the user or installer can paint or coat the bar as they choose).

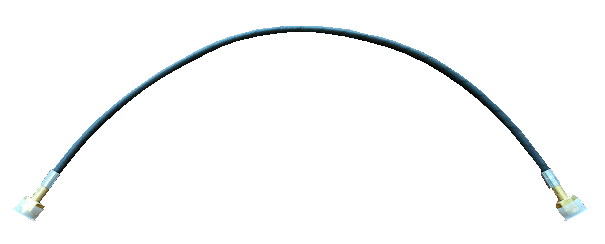

- Cryogenic: Flexible rubber hose, CGA connection for the specific gas.

- CGA540 Oxygen Deward type 230PSI minimum pressure.

- Low pressure (50-55psi) emergency input CGA540 coupling port, for a backup header to medical gas automatic manifold deward type.

- Liquid Nitrogen cryogenic systems CGA 580 connection for Dewar type cylinders, complies with NFPA99-2015, includes emergency inlet in low pressure stage.

- 100-220 V 50-60 Htz. power supply

- External evaporators in case of an oxygen over demand that freezes the system

- A source primary supply bulk (microbulk) in case of an oxygen over demand that freezes the manifold, (The manifold becomes a secondary or backup source).

- Belden STP (Shield Twisted Pair) #8461ZH or #8208.

- Voltage variations in the electrical power supply.

- Main power supply with emergency power plants.

- Intermittent Power supply (power lost and regained often in a short time).

- Check ground connection (to protect from unwanted discharges).

- Install a system against voltage variations and power backup (Non-Break).

- Install a system with a surge suppressor (against power surges and discharges).

Brochure

Download:No Available.

Legal Notice

Intellectual and industrial property: All rights reserved.- All access to this website is subject to the following conditions: The reproduction, permanent storage and dissemination of the contents or any other use that has a public or commercial purpose is forbidden without prior written notice and approval of Grupo Arigmed S. de R.L. de C.V.

- All documents, images and contents, on this website are from the Intellectual property of Grupo Arigmed S. de R.L. de C.V., any type of copy, plagiarism or similarity in those (documents, images and contents), will be object of legal actions to avoid its use by unauthorized persons, organizations or companies, as well to compensate author´s damage caused.